What is gantry milling machine

Gantry milling machine is called gantry milling for short. It is a milling machine with portal frame and horizontal long bed. The planer milling machine can use multiple milling cutters to process the surface at the same time, with high machining accuracy and production efficiency. It is suitable for processing the plane and bevel of large workpieces in batch and mass production. CNC gantry milling machine can also process space curved surface and some special parts.

Whitney created the horizontal milling machine in 1818; brown created the first universal milling machine in 1862 for milling the spiral grooves of twist drills, which is the prototype of the lifting table milling machine; the gantry milling machine appeared around 1884; the semi-automatic milling machine appeared in 1920s, and the worktable can complete the automatic "feed fast" or "fast feed" by using the stop Transformation.

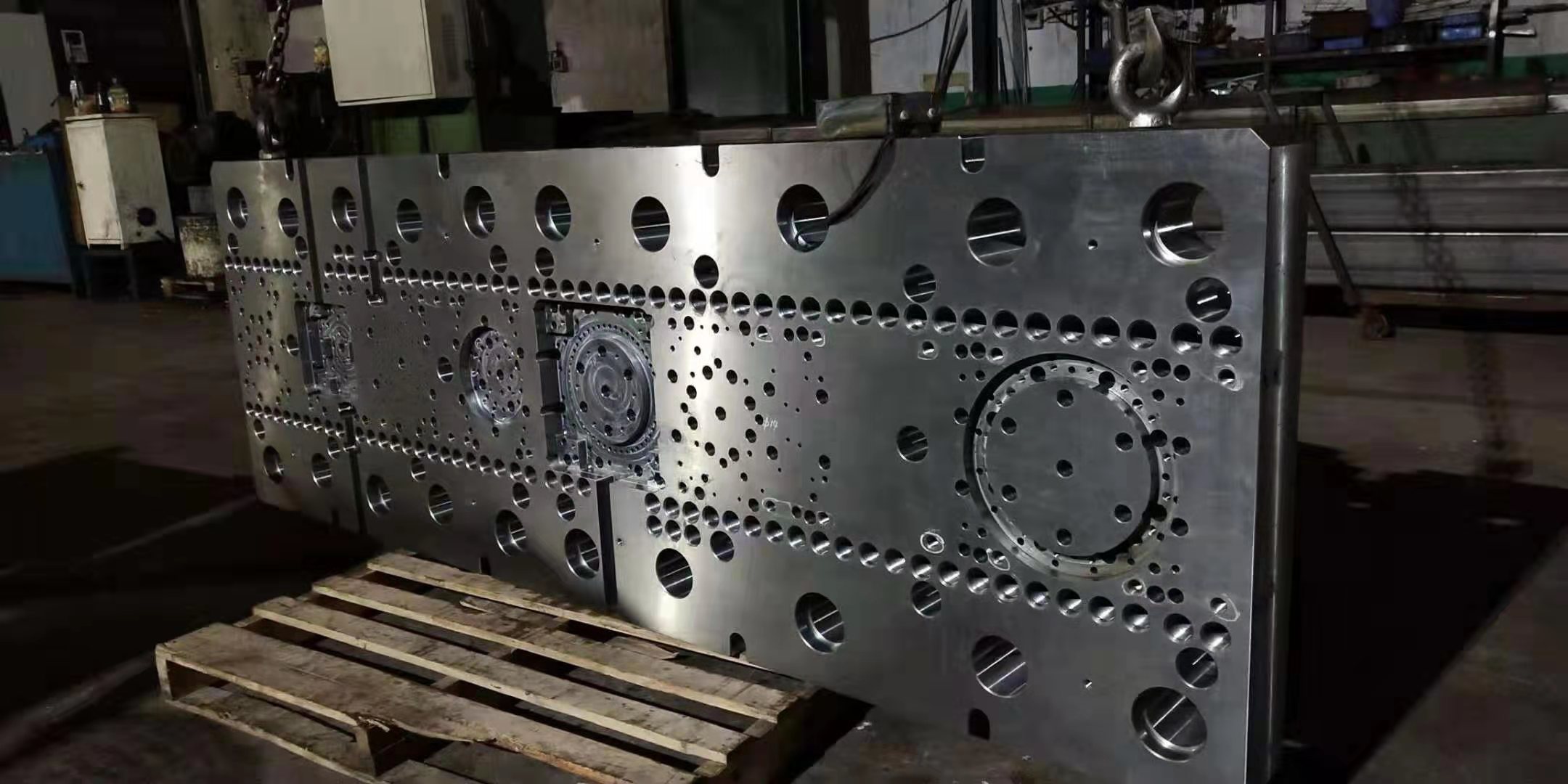

Milling machine with portal frame and horizontal long bed. The planer milling machine has high machining accuracy and productivity, and is suitable for machining large-scale workpiece plane and bevel in batch and mass production. CNC gantry milling the gantry of the world's largest gantry milling machine (xka28105 × 300)

The machine can also process space curved surface and some special parts. The gantry milling machine (see Figure) is composed of a column and a top beam to form a portal frame. The crossbeam can be lifted and lowered along the two column guide rails (see [[machine guide]]). There are 1-2 milling heads with vertical spindle on the crossbeam, which can move horizontally along the crossbeam guide rail. A milling head with a horizontal spindle can be installed on the two vertical columns respectively, which can move up and down the column guide rail. These milling heads can process several surfaces at the same time. Each milling head has a separate motor (power up to 150 kW), speed change mechanism, control mechanism and spindle components (see machine tool spindle), etc. During machining, the workpiece is installed on the worktable and the longitudinal feed motion is made accordingly (see machine tool). The total weight of large gantry milling machine (Table 6 × 22 m) is 850 tons. There are also some variants of the gantry milling machine to adapt to different processing objects. ① Gantry milling and boring machine: the crossbeam is equipped with milling and boring head, and its main shaft (sleeve or RAM) can make axial motor feed and has motion fine-tuning device, and the fine-tuning speed can be as low as 5mm / min. ② Bridge type gantry milling machine: the worktable and workpiece do not move, but move by gantry. It is characterized by small floor area, large bearing capacity, gantry travel up to 20 meters, easy to process special or heavy workpiece The shape is similar to the planer, the difference is that the cross beam and column are not equipped with planer tool rest but milling tool rest with spindle box, and the reciprocating motion of the longitudinal worktable of the planer is not the main motion, but the feed motion, and the rotation motion of the milling tool is the main motion. In the planer milling machine, multiple milling cutters can be used to process the surface at the same time, so the production efficiency is relatively high. It is suitable for batch production and single piece production to process medium-sized and large workpieces.

-

02-20

What is the most important parameter in CNC machining of Jiangmen?

We usually do CNC, no matter which programming software you use, no matter which version you use, in the final analysis, we are setting the following parameters.1: The cutting depth is the cutting dep

-

02-20

Cleaning steps of lubricating device of CNC milling machine

Many parts of the lubricating device of CNC milling machine need to be cleaned regularly. The specific cleaning methods are as follows. (1) Cleaning method of oil rope and felt. Oil rope and linole

-

02-20

How to choose the right cutting tool for Jiangmen CNC machining

How to select cutting tools reasonably in Jiangmen CNC machining The selection of cutting tools is carried out under the condition of human-computer interaction of NC programming. The tool and hand

-

02-20

What are the rust removal methods of Jiangmen CNC machining precision parts

The machining of fine parts or parts, such as bearings, etc. will produce embroidered corrosion due to improper storage conditions or rust prevention, which can not be treated by mechanical method at